White diodes. White LED

White LED

Powerful white LED

There are two types of white LEDs:

- Multi-chip LEDs, more often three-component (RGB LEDs), containing three semiconductor emitters of red, green and blue light, combined in one housing.

- Phosphor LEDs, created on the basis of an ultraviolet or blue LED, containing a layer of a special phosphor that, as a result of photoluminescence, converts part of the LED radiation into light in a relatively wide spectral band with a maximum in the yellow region (the most common design). The emission of the LED and phosphor, when mixed, produce white light of various shades.

History of invention

The first red semiconductor emitters for industrial use were obtained by N. Holonyak in 1962. In the early 70s, yellow and green LEDs appeared. The light output of early low-efficiency devices reached the single lumen level by 1990. In 1993, Suji Nakamura, an engineer at Nichia (Japan), created the first high-brightness blue LED. Almost immediately, LED RGB devices appeared, since blue, red and green colors made it possible to obtain any color, including white. White phosphor LEDs first appeared in 1996. Subsequently, the technology developed rapidly and by 2005, the luminous output of LEDs reached 100 lm/W or more. LEDs appeared with different shades of glow, the quality of light made it possible to compete with incandescent lamps and with already traditional fluorescent lamps. The use of LED lighting devices in everyday life, in indoor and outdoor lighting, has begun.

RGB LEDs

White light can be created by mixing different colored LEDs. The most common trichromatic design is made from red (R), green (G) and blue (B) sources, although bichromatic, tetrachromatic and more multi-chromatic variants are found. A multicolor LED, unlike other RGB semiconductor emitters (luminaires, lamps, clusters), has one complete housing, most often similar to a single-color LED. The LED chips are located next to each other and share a common lens and reflector. Since semiconductor chips have a finite size and their own radiation patterns, such LEDs most often have uneven angular color characteristics. In addition, to obtain the correct color ratio, it is often not enough to set the design current, since the light output of each chip is unknown in advance and is subject to changes during operation. To set the desired shades, RGB lamps are sometimes equipped with special control devices.

The spectrum of an RGB LED is determined by the spectrum of its constituent semiconductor emitters and has a pronounced line shape. This spectrum is very different from the spectrum of the sun, therefore the color rendering index of the RGB LED is low. RGB LEDs make it possible to easily and widely control the color of the glow by changing the current of each LED included in the triad, adjusting the color tone of the white light they emit directly during operation - up to obtaining individual independent colors.

Multicolor LEDs have a dependence of light output and color on temperature due to the different characteristics of the emitting chips that make up the device, which results in a slight change in the color of the glow during operation. The service life of a multicolor LED is determined by the durability of the semiconductor chips, depends on the design and most often exceeds the service life of phosphor LEDs.

Multicolor LEDs are used primarily for decorative and architectural lighting, in electronic signage and video screens.

Phosphor LEDs

Spectrum of one of the phosphor LED options

Combining a blue (more often) or ultraviolet (less often) semiconductor emitter and a phosphor converter allows you to produce an inexpensive light source with good characteristics. The most common design of such an LED contains a blue gallium nitride semiconductor chip modified with indium (InGaN) and a phosphor with maximum re-emission in the yellow region - yttrium-aluminum garnet doped with trivalent cerium (YAG). Part of the power of the initial radiation of the chip leaves the LED body, dissipating in the phosphor layer, the other part is absorbed by the phosphor and re-emitted in the region of lower energy values. The re-emission spectrum covers a wide region from red to green, but the resulting spectrum of such an LED has a pronounced dip in the green-blue-green region.

Depending on the composition of the phosphor, LEDs are produced with different color temperatures (“warm” and “cold”). By combining different types of phosphors, a significant increase in the color rendering index (CRI or R a) is achieved, which suggests the possibility of using LED lighting in conditions critical to the quality of color rendering.

One way to increase the brightness of phosphor LEDs while maintaining or even reducing their cost is to increase the current through the semiconductor chip without increasing its size - increasing the current density. This method is associated with a simultaneous increase in requirements for the quality of the chip itself and the quality of the heat sink. As the current density increases, the electric fields in the bulk of the active region reduce the light output. When the limiting currents are reached, since areas of the LED chip with different impurity concentrations and different band gaps conduct current differently, local overheating of the chip areas occurs, which affects the light output and the durability of the LED as a whole. In order to increase the output power while maintaining the quality of spectral characteristics and thermal conditions, LEDs are produced containing clusters of LED chips in one housing.

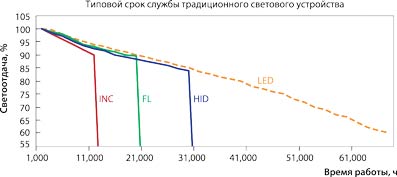

One of the most discussed topics in the field of polychrome LED technology is its reliability and durability. Unlike many other light sources, an LED changes its light output (efficiency), radiation pattern, and color tint over time, but rarely fails completely. Therefore, to assess the useful life, for example for lighting, a level of reduction in luminous efficiency of up to 70% of the original value (L70) is taken. That is, an LED whose brightness decreases by 30% during operation is considered to be out of order. For LEDs used in decorative lighting, a brightness reduction level of 50% (L50) is used as an assessment of the lifespan.

The service life of a phosphor LED depends on many parameters. In addition to the manufacturing quality of the LED assembly itself (the method of attaching the chip to the crystal holder, the method of attaching the current-carrying conductors, the quality and protective properties of the sealing materials), the lifetime mainly depends on the characteristics of the emitting chip itself and on changes in the properties of the phosphor over the course of operation (degradation). Moreover, as numerous studies show, temperature is considered the main factor influencing the service life of an LED.

Effect of temperature on LED service life

During operation, a semiconductor chip emits part of the electrical energy in the form of radiation and part in the form of heat. Moreover, depending on the efficiency of such conversion, the amount of heat is about half or more for the most efficient emitters. The semiconductor material itself has low thermal conductivity; in addition, the materials and design of the case have a certain non-ideal thermal conductivity, which leads to the heating of the chip to high temperatures (for a semiconductor structure). Modern LEDs operate at chip temperatures in the region of 70-80 degrees. And a further increase in this temperature when using gallium nitride is unacceptable. High temperature leads to an increase in the number of defects in the active layer, leads to increased diffusion, and a change in the optical properties of the substrate. All this leads to an increase in the percentage of non-radiative recombination and absorption of photons by the chip material. An increase in power and durability is achieved by improving both the semiconductor structure itself (reducing local overheating), and by developing the design of the LED assembly, and improving the quality of cooling of the active area of the chip. Research is also being conducted with other semiconductor materials or substrates.

The phosphor is also susceptible to high temperatures. With prolonged exposure to temperature, re-emitting centers are inhibited and the conversion coefficient, as well as the spectral characteristics of the phosphor, deteriorate. In early and some modern polychrome LED designs, the phosphor is applied directly to the semiconductor material and the thermal effect is maximized. In addition to measures to reduce the temperature of the emitting chip, manufacturers use various methods to reduce the influence of chip temperature on the phosphor. Isolated phosphor technologies and LED lamp designs, in which the phosphor is physically separated from the emitter, can increase the service life of the light source.

The LED body, made of optically transparent silicone plastic or epoxy resin, is subject to aging under the influence of temperature and begins to dim and yellow over time, absorbing part of the energy emitted by the LED. Reflective surfaces also deteriorate when heated - they interact with other elements of the body and are susceptible to corrosion. All these factors together lead to the fact that the brightness and quality of the emitted light gradually decreases. However, this process can be successfully slowed down by ensuring efficient heat removal.

Phosphor LED design

Diagram of one of the white LED designs. MPCB is a high thermal conductivity printed circuit board.

A modern phosphor LED is a complex device that combines many original and unique technical solutions. The LED has several main elements, each of which performs an important, often more than one function:

All LED design elements experience thermal stress and must be selected taking into account the degree of their thermal expansion. And an important condition for a good design is manufacturability and low cost of assembling an LED device and installing it in a lamp.

Brightness and quality of light

The most important parameter is not even the brightness of the LED, but its luminous efficiency, that is, the light output from each Watt of electrical energy consumed by the LED. The luminous efficiency of modern LEDs reaches 150-170 lm/W. The theoretical limit of the technology is estimated at 260-300 lm/W. When assessing, it is necessary to take into account that the efficiency of a lamp based on LEDs is significantly lower due to the efficiency of the power source, the optical properties of the diffuser, reflector and other design elements. In addition, manufacturers often indicate the initial efficiency of the emitter at normal temperature. While the temperature of the chip during operation is much higher. This leads to the fact that the actual efficiency of the emitter is 5 - 7% lower, and that of the lamp is often twice as low.

The second equally important parameter is the quality of the light produced by the LED. There are three parameters to assess the quality of color rendering:

Phosphor LED based on an ultraviolet emitter

In addition to the already widespread combination of a blue LED and YAG, a design based on an ultraviolet LED is also being developed. A semiconductor material capable of emitting in the near ultraviolet region is coated with several layers of a phosphor based on europium and zinc sulfide activated by copper and aluminum. This mixture of phosphors gives re-emission maxima in the green, blue and red regions of the spectrum. The resulting white light has very good quality characteristics, but the efficiency of such conversion is still low.

Advantages and disadvantages of phosphor LEDs

Considering the high cost of LED lighting sources compared to traditional lamps, there are compelling reasons to use such devices:

- The main advantage of white LEDs is their high efficiency. Low specific energy consumption allows their use in long-term autonomous and emergency lighting sources.

- High reliability and long service life suggest possible savings on lamp replacement. In addition, the use of LED light sources in hard-to-reach areas and outdoor conditions reduces maintenance costs. Combined with high efficiency, there are significant cost savings when using LED lighting in some applications.

- Light weight and size of devices. LEDs are small in size and suitable for use in hard-to-reach places and small portable devices.

- The absence of ultraviolet and infrared radiation in the spectrum allows the use of LED lighting without harm to humans and for special purposes (for example, for illuminating rare books or other objects exposed to light).

- Excellent performance at sub-zero temperatures without reducing, and often even improving, parameters. Most types of LEDs exhibit greater efficiency and longer life as temperatures drop, but power, control, and design components may have the opposite effect.

- LEDs are inertia-free light sources; they do not require time to warm up or turn off, such as fluorescent lamps, and the number of on and off cycles does not negatively affect their reliability.

- Good mechanical strength allows LEDs to be used in harsh operating conditions.

- Ease of power regulation by both duty cycle and supply current regulation without compromising efficiency and reliability parameters.

- Safe to use, no risk of electric shock due to low supply voltage.

- Low fire hazard, possibility of use in conditions of explosion and fire hazard due to the absence of incandescent elements.

- Moisture resistance, resistance to aggressive environments.

- Chemical neutrality, no harmful emissions and no special requirements for disposal procedures.

But there are also disadvantages:

Lighting LEDs also have features inherent in all semiconductor emitters, taking into account which the most successful application can be found, for example, the direction of radiation. The LED shines only in one direction without the use of additional reflectors and diffusers. LED luminaires are best suited for local and directional lighting.

Prospects for the development of white LED technology

Technologies for manufacturing white LEDs suitable for lighting purposes are under active development. Research in this area is stimulated by increased public interest. The prospect of significant energy savings is attracting investment in process research, technology development and the search for new materials. Judging by the publications of manufacturers of LEDs and related materials, specialists in the field of semiconductors and lighting engineering, it is possible to outline development paths in this area:

See also

Notes

- , p. 19-20

- Cree MC-E LEDs containing red, green, blue and white emitters. LED Professional. Archived

- Vishay VLMx51 LEDs containing red, orange, yellow and white emitters. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Cree XB-D and XM-L Multicolor LEDs. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Cree XP-C LEDs containing six monochromatic emitters. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Nikiforov S.“S-class” of semiconductor lighting technology // Components and technologies: magazine. - 2009. - No. 6. - P. 88-91.

- Truson P. Halvardson E. Advantages of RGB LEDs for lighting devices // Components and technologies: magazine. - 2007. - No. 2.

- , p. 404

- Nikiforov S. Temperature in the life and operation of LEDs // Components and technologies: magazine. - 2005. - No. 9.

- LEDs for interior and architectural lighting (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Siang Ling Oon LED solutions for architectural lighting systems // : magazine. - 2010. - No. 5. - P. 18-20.

- RGB LEDs for use in electronic displays (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Turkin A. Gallium nitride as one of the promising materials in modern optoelectronics // Components and technologies: magazine. - 2011. - No. 5.

- LEDs with high CRI values. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Cree's EasyWhite technology. LEDs Magazine. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Nikiforov S., Arkhipov A. Features of determining the quantum yield of LEDs based on AlGaInN and AlGaInP at different current densities through the emitting crystal // Components and technologies: magazine. - 2008. - No. 1.

- Nikiforov S. Now electrons can be seen: LEDs make electric current very visible // Components and technologies: magazine. - 2006. - No. 3.

- LEDs with a matrix arrangement of a large number of semiconductor chips (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- White LED Lifetime Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Types of LED defects and methods of analysis (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- , p. 61, 77-79

- LEDs from SemiLEDs (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- GaN-on-Si Silicon LED Research Program. LED Professional. Retrieved November 10, 2012.

- Cree Isolated Phosphor Technology. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Turkin A. Semiconductor LEDs: history, facts, prospects // Semiconductor lighting technology: magazine. - 2011. - No. 5. - P. 28-33.

- Ivanov A.V., Fedorov A.V., Semenov S.M. Energy-saving lamps based on high-brightness LEDs // Energy supply and energy saving – regional aspect: XII All-Russian meeting: materials of reports. - Tomsk: St. Petersburg Graphics, 2011. - pp. 74-77.

- , p. 424

- White LEDs with high light output for lighting needs. Phys.Org™. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- LED Lighting Basics. U.S. Department of Energy. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Sharakshane A. Scales for assessing the quality of the spectral composition of light - CRI and CQS // Semiconductor lighting technology: magazine. - 2011. - No. 4.

- Ultraviolet LEDs SemiLED with a wavelength of 390-420 nm. (English) . LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- , p. 4-5

- Active cooling systems from the Nuventix campaign. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- N.P.Soschin Modern photoluminescent materials for efficient solid-state lighting devices. Conference materials. (Russian) (February 1, 2010). Archived

- O.E.Dudukalo, V.A.Vorobiev(Russian) (May 31, 2011). Archived from the original on October 27, 2012.

- Tests of accelerated temperature degradation of phosphors (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Research and Markets Releases New 2012 Report on LED Phosphor Materials (English) . LED Professional. Archived from the original on December 10, 2012. Retrieved November 30, 2012.

- Intematix presented a set of phosphors for high-quality color rendering (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Lumi-tech proposed SSE phosphor for white LEDs. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Red phosphorus from Intematix (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Quantum dot LEDs (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Osram's 609 nm red all-diode prototype with 61% efficiency. LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Transition to GaN-on-Si structure (English). LED Professional. Archived from the original on November 23, 2012. Retrieved November 10, 2012.

- Tim Whitaker Joint venture to make ZnSe white LEDs (English) (December 6, 2002). Archived from the original on October 27, 2012. Retrieved November 10, 2012.

- , p. 426

Literature

- Schubert F.E. LEDs. - M.: Fizmatlit, 2008. - 496 p. - ISBN 978-5-9221-0851-5

- Weinert D. LED Lighting: A Handbook. - Philips, 2010. - 156 p. - ISBN 978-0-615-36061-4

Links

- US Department of Energy website about LED lighting

- Led Professional. Scientific and technical journal about LEDs and LED lighting, Austria

- LEDs Magazine. Scientific and technical magazine about LEDs and LED lighting. USA

- Semiconductor lighting technology. Russian magazine about LEDs and LED lighting

| Incandescent | Incandescent lamp Halogen lamp |

|---|---|

| Fluorescent | |

LED (Lighting Emission Diode) - LEDs with intense light emission are well known to everyone. About 10 years ago (in Russia) they made a “quiet revolution in lighting,” especially where mobility, low specific energy consumption, reliability and long service life are needed. It seemed that the ideal source of light that bikers and tourists, as well as hunters and fishermen, speleologists and climbers were eager to receive, was already “here and now.” And it is enough to extend your hand, accumulating a few killed raccoons, and there will be “peace on earth, good will to men.” Now, we can say that these 10 years were not in vain and the LED reality turned out to be interesting, diverse and provides new opportunities that had not even occurred to us before.

Rice. 2 Design of the Luxeon LED from Lumileds lighting.* (“Description and principle of operation of LED lamps” Group of Energy Saving Companies )

Rice. 3 Blue LED with monochromatic emission. . (“LED - technology, principle of operation. Pros and cons of LED.”

OPERATING PRINCIPLE .

An LED is primarily a diode. That is, a kind of cunning pebble with a p-n junction inside. In other words, contact of two semiconductors with different types of conductivity. Which, under certain conditions, emits light through the process of recombination (mutual constructive suicide) of electrons and holes.

Typically, the greater the current through an LED, the more electrons and holes enter the recombination zone per unit time and more light is emitted at the output. But the current cannot be increased greatly - due to the internal resistance of the semiconductor and the p-n junction, the LED may overheat, which leads to its accelerated aging or failure.

To obtain a significant light flux, multilayer semiconductor structures - heterostructures - are created. For the development of semiconductor heterostructures for high-speed optoelectronics, Zhores Alferov, a Russian physicist, received the Nobel Prize in 2000.

TWO WORDS FOR THE STORY.

The first red semiconductor emitters for industrial use were produced in 1962. In the 60s and 70s, LEDs based on gallium phosphide and arsenide were created, emitting in the yellow-green, yellow and red regions of the spectrum. They were used in light indicators and alarm systems. In 1993, the Nichia company (Japan) created the first high-brightness blue LED. Almost immediately, LED RGB devices appeared, since blue, red and green colors made it possible to obtain any color, including white. White phosphor LEDs first appeared in 1996. Subsequently, the technology developed rapidly and by 2005, the luminous output of LEDs reached more than 100 lm/W.

WHITE LIGHT.

A conventional color LED emits a narrow spectrum of light waves (monochromatic radiation). This is good for alarm devices. And for lighting we need white LEDs and use different technologies..

For example, color mixing using RGB technology. Red, blue and green LEDs are densely placed on one matrix, the radiation of which is mixed using an optical system, such as a lens. The result is white light.

Rice. 4 Emission spectrum of an RGB LED. ("Wikipedia")

Or, let’s say, a phosphor is used, or more precisely, several phosphors are applied to an LED and, as a result of mixing colors, white or close to white light is obtained. White LEDs with phosphors are cheaper than RGB matrices, which makes them possible to use for lighting.

Rice. 5 Emission spectrum of a white LED with a phosphor.* (Wikipedia)

Rice. 6 White LED with phosphor. Diagram of one of the white LED designs.

MRSV is a printed circuit board with high thermal conductivity. * ("Wikipedia")

The current-voltage characteristic of LEDs in the forward direction is nonlinear and the current begins to flow from a certain threshold voltage. In the main modes of LED emission, the current depends exponentially on the voltage and small changes in voltage lead to large changes in current. And since the light output is directly proportional to the current, the brightness of the LED turns out to be unstable. Therefore, the current has to be stabilized. The brightness of LEDs can, for example, be adjusted using pulse width modulation (PWM), which requires an electronic device that supplies pulsed high-frequency signals to the LED. Unlike incandescent lamps, the color temperature of LEDs changes very little when dimming .

Advantages and disadvantages of phosphor LEDs.

In an LED, unlike an incandescent or fluorescent lamp, electric current is converted directly into light radiation, and losses are therefore relatively small.

- The main advantage of white LEDs is high efficiency, low specific energy consumption and high luminous efficiency - 160-170 Lumens/Watt.

- High reliability and long service life.

- The light weight and size of LEDs allow them to be used in small-sized portable flashlights.

- The absence of ultraviolet and infrared radiation in the spectrum allows the use of LED lighting without harmful consequences, since ultraviolet radiation, especially in the presence of ozone, has a strong effect on organic matter, and infrared radiation can lead to burns.

- The specific power density indicator, which characterizes the luminous flux density, of a standard fluorescent lamp is 0.1-0.2 W/cm², and for a modern white LED it is about 50 W/cm².

- Work at sub-zero temperatures without reducing, and often even improving, parameters.

- LEDs are inertia-free light sources; they do not require time to warm up or turn off, such as fluorescent lamps, and the number of on and off cycles does not affect their reliability.

- The LED is mechanically robust and extremely reliable.

- Easy to adjust brightness.

- LED is a low-voltage electrical device, and therefore safe.

- Low fire hazard, can be used in explosive environments.

- Moisture resistance, resistance to aggressive environments.

But there are also minor drawbacks:

- White LEDs are more expensive and more complex to produce than incandescent lamps, although their price is gradually decreasing.

- Low quality of color rendering, which, however, is gradually improving.

- Powerful LEDs require a good cooling system.

- Rapid deterioration of performance and even failure at elevated ambient temperatures of more than 60 - 80°C.

- Phosphors also do not like high temperatures, because... the conversion coefficient and spectral characteristics of the phosphor deteriorate.

- The LED housing is made of optically transparent silicone plastic or epoxy resin, which ages and, under the influence of temperature, dims and turns yellow, absorbing part of the light flux.

- Modern, powerful, ultra-bright LEDs can blind and damage a person’s vision.

- The contacts are susceptible to corrosion failures. Reflectors (usually made of plastic, coated with a thin layer of aluminum), at elevated temperatures, deteriorate their properties over time, and the brightness and quality of the emitted light gradually deteriorate.

REAL LIFE OF WHITE LEDS.

Rice. 7 Reduction of light output during operation and failure behavior of incandescent lamps (INC), fluorescent lamps (FL), high-intensity discharge lamps (HID) and LED lamps (not to scale, typical curves shown).

Magazine "Time of Electronics", Article "Determining the service life of LEDs"

Written by Eric Richman (EricRichman), senior researcher,PacificNorthwestNationalLaboratories (PNNL)

We have known about the 100,000 hour service life of LEDs for many years. What is it really like?

“In the early days of LEDs, the most commonly reported operating life was 100,000 hours. However, no one has been able to explain where this magic number came from. Most likely, it was dictated by the market, not science. The first LED manufacturer to indicate the service life based on real technical parameters was Philips Lumileds, with its brainchild, the Luxeon LED. The durability of the first Luxeon devices, with a specified drive current of 350 mA and a junction temperature of 90 degrees Celsius, was estimated at 50,000 hours. This means that after 50,000 hours of operation of the LED under given conditions, its luminous flux will decrease to 70% of the original.”

Article “Uncharted Waters: Determining the Durability of LED Luminaires”, Magazine "Time of Electronics", Timur Nabiev.

Currently, there is no standard defining what “service life” actually means for LEDs. There are also no standards that quantify the color change of an LED over time. It is not defined how the LED should operate after this period. Some leading companies have been forced to define their own criteria for service life. For example, two threshold values of luminous flux were selected: - 30% and 50%, upon reaching which the LED is considered to be out of order. And these values depend on the perception of the emitted light by the human eye.

1) - 30% reduction in luminous flux of reflected LED light. That is, when an LED flashlight illuminates the road, surrounding objects, etc.

2) - 50% reduction in luminous flux when direct light is used, for example in traffic lights, road signs, parking lights of cars....

And other first-line companies choose only one threshold value - 50%.

Moreover, degradation of LEDs and LED flashlights occurs at all levels, starting from the p-n junction and ending with the transparent front plastic lens of the flashlight body. Moreover, low-power signal and indicator LEDs can last for decades. And ultra-bright modern LEDs, which often work under intense conditions, both in current and temperature, lose their brightness much faster. Thus, the real service life of high-quality modern LEDs is from several months to five to six years in continuous operation. For example, Petzl claims a service life of its LEDs in flashlights of at least 5,000 hours. By the way, leading companies often claim a shorter service life for their devices than those of “super-duper-budget”, often Asian manufacturers, who simply increase the current level and achieve a bright glow. When purchasing flashlights, all the characteristics of the LEDs correspond to the passport, in which they always write about the magic 100,000 hours. But the actual service life of such LEDs may not exceed 1000...1500 hours and during this time the luminous flux decreases by at least 2 times.

BATTERIES AND ACCUMULATORS.

During operation, batteries and accumulators are discharged, the supply voltage decreases, the brightness of the LEDs and the effective luminous flux gradually decreases.

Brightness decrease curve during natural battery discharge.

Electronically adjustable brightness. Illumination of 0.25 lux is measured at a distance of 2 meters from the lamp. (This is the illumination provided by the moon during a full moon).

To improve the effective light output, electronic regulation (stabilization) of the supply voltage is used. The current strength is controlled by a special microcircuit, which ensures stable brightness throughout the entire operating time. The idea was first developed by Petzl. Thanks to the electronic circuit, the flashlights have stable characteristics throughout the entire operating time, and then go into emergency mode (0.25 lux). A brightness of 0.25 lux is the illumination produced by a full moon high above the horizon on a clear day.

Optimal power sources.

1. For LED flashlights today, these are of course alkaline or lithium (lithium-ion) disposable batteries. Lithium batteries are lightweight, have high capacity, and perform well at low temperatures. These are, for example, Li-MnO2 batteries CR123 or CR2 with a voltage of 3V or Li-FeS2 (lithium iron disulfide) batteries with a voltage of 1.5V, but not all LED lights are compatible with lithium batteries - please check the instructions.

2. Batteries.

|

Characteristics |

Nickel-cadmium |

Nickel metal hydride |

Lithium- |

|

Rated voltage, V |

|||

|

Typical capacity, Ah |

|||

|

Specific energy: |

30 - 60 |

40 - 80 |

100 - 180 |

|

Maximum constant discharge current, up to |

5 (10) WITH |

3 WITH |

2 WITH |

|

Charge mode |

Standard: current 0.1 WITH 16 hours |

Standard: current 0.1 WITH 16 hours |

Charge current 0.1-1 WITH |

|

Capacity return coefficient (Discharge/Charge) |

|||

|

Operating temperature range, ºС |

|||

|

Self-discharge (in%): |

4 - 5 |

Current 1C means a current numerically equal to the rated capacity.

* From the article: A.A. Taganova “LITHIUM CURRENT SOURCES FOR PORTABLE ELECTRONIC EQUIPMENT”

Nickel-cadmium

(NiCd) have a small weight and dimensions, poor environmental friendliness - cadmium is a terribly harmful metal to health. Explosive with a durable and sealed housing, having microvalves for automatic release of gases, but, at the same time, fairly high reliability and high charging and discharging currents. They are often used in on-board equipment and for devices that consume a lot of power, such as diving lights. The only type of battery that can be stored discharged, unlike nickel-metal hydride (Ni-MH) batteries, which must be stored fully charged, and lithium-ion batteries (Li-ion), which must be stored at 40% charge on battery capacity

Nickel metal hydride

(Ni-MH) were developed to replace nickel-cadmium (NiCd). NiMH batteries are practically free of the “memory effect” and complete discharge is not often required. Environmentally friendly. The most favorable operating mode: low current charge, 0.1 rated capacity, charging time - 15-16 hours (manufacturer's recommendation). It is recommended to store batteries fully charged in the refrigerator, but not below 0 C?. They provide a 40-50 percent advantage in specific energy intensity compared to the previous favorite - NiCd. They have significant potential for increasing energy density. Environmentally Friendly - Contains only mild toxins and is recyclable. Inexpensive. Available in a wide range of sizes, parameters and performance characteristics.

DIMENSIONS AND FLASHING LIGHTS.

12) TL-LD1000 CatEye

13) RAPID 1 (TL-LD611-F)CatEye

European safety practice involves the use of not only rear, but also front side lights.

Rapid 1 front (white) and rear (red) lights, with the function of recharging batteries via a USB port and a charge level indicator. The high power of the flashlight is achieved by using an SMD LED and OptiCube ™ technology. The shimmer of CatEye Rapid 1 attracts the attention of motorists and passers-by.

4 operating modes provide optimal selection of parameters, both at night and during the day. CatEye Rapid 1 comes with a low profile SP-12 Flextight™ bracket, which is compatible with all new RM-1.

Operating time: 5 hours (continuous mode)

25 hours (fast and pulse modes)

40 hours (flashing mode)

Lighting memory mode (last mode you turned on)

Li-ion USB battery - rechargeable

Weight about 41 g. with mount and battery

Clip for clothes.

14) SOLAR (SL-LD210)CatEye

The cyclist must be visible not only from the back, but also from oncoming traffic, not only at night, but also during the day - with the side light on.

One 5mm LED turns on automatically in flashing mode when you start driving in the dark. The built-in solar battery charges within 2 hours in good weather conditions and provides up to 5 hours of operation. Available in front and rear mounting models, comes with the new Flextight™ bracket. Weight 44 g. including bracket and battery

DYNAMO - LANTERNS (BUGS).

15) BLUEBIRD

3- LEDs, brightness 6 lm, 3 modes, two constant (1LED and 3LED), one flashing (3LED), operation after recharging: - about 40 minutes (3LED); - about 90 minutes (1LED), weight with handlebar mount 115g.

Impression:

Well, a very good flashlight, IMHO, both for the size on a bicycle and for lighting in “manual mode” in a tent, at a rest stop, and in general. In civilized urban conditions, when there is general lighting and good vision, it can even be the main flashlight, especially if the road is known. The speaker turns easily, does not make much noise, and the battery charges quickly. Shines a good white light. OK!

16) Charger Energenie EG-PC-005 for mobile phones with manual drive and flashlight. Installed on the bike.

Energy is generated using a dynamo with a crank. Rotating the handle for three minutes charges the mobile phone for at least 8 minutes of talk time. Rotating the crank for 10 minutes provides bright light for at least 50 minutes.

Specifications

- Output voltage - 4.0-5.5V

- Outgoing current up to 400 mA

- Built-in Ni-MH rechargeable 80 mAH battery allows for at least 500 full recharges

- 2 flashlights:

-head: LED, at maximum charge illuminates up to 10 meters.

-rear: red LED. - Two modes: constant light (3LED), - strobe (3LED)

- Net weight 0.2 kg

Scope of delivery

- Charger Energenie EG-PC-005 for mobile phones with manual drive, bicycle mount and front flashlight

- rear light with 1.2m cable

- cable for Nokia phones

- 6 adapters for other phones

Impression:

Not a bad size, suitable for lighting in a tent and for all kinds of household needs. LEDs are not the best - with a clear bluish tint, which is not gut. Unfortunately, the battery has some difficulty coping with a double load (3LED) in front and a red light in the back - and “sit down” quickly enough. I had to turn off and throw out the red tail light and, IMHO, it got better (longer). The speaker lever is easy to turn, there is not much noise, and its own battery charges without problems. I had to charge both my mobile phone and my e-reader while traveling. With some persistence and patience, this can be done, but it will take some work. When the flashlight operates under an external load, the force on the lever increases significantly and you have to sweat a little. But the overall assessment of this device is a useful thing.

17) Charger Energenie EG-SC-001 for mobile phones with a battery charged from light and from the mains and with a built-in LED flashlight.

The presence of a USB connector allows you to quickly charge the built-in battery, which is equipped with protection against overcharge, deep discharge, overload and short circuit. If the battery is low, the warning system is activated. Has a built-in LED flashlight.

Charges the following mobile phones and is equipped with the following connectors: Nokia 6101 and 8210 series, Samsung A288 series, Mini USB 5pin, Sony Ericsson K750 series, Micro-USB.

Solar cells Energenie EG-SC-001 allows you to charge mobile devices while hiking, of course in sunny weather.

Specifications

- outgoing voltage - 5.4V

- outgoing current up to 1400 mA

- built-in Li-ion rechargeable battery 2000 mAH allows at least 500 full recharges

- built-in USB connector 5-6V

- bright LED flashlight

- dimensions: 116*49*26 mm

- weight 130 g

Scope of delivery

- Charger

- AC220V-DC5V USB Power Adapter A black

- 5 adapters for charging mobile phones

- USB connection cable.

The intensity of photosynthesis under red light is maximum, but under red light alone, plants die or their development is disrupted. For example, Korean researchers have shown that when illuminated with pure red, the mass of grown lettuce is greater than when illuminated with a combination of red and blue, but the leaves contain significantly less chlorophyll, polyphenols and antioxidants. And the Faculty of Biology of Moscow State University has established that in the leaves of Chinese cabbage under narrow-band red and blue light (compared to illumination with a sodium lamp), the synthesis of sugars is reduced, growth is inhibited and flowering does not occur.

Rice. 1 Leanna Garfield Tech Insider - Aerofarms

What kind of lighting is needed to get a fully developed, large, fragrant and tasty plant with moderate energy consumption?

How to evaluate the energy efficiency of a lamp?

Basic metrics for assessing the energy efficiency of phytolight:

- Photosynthetic Photon Flux (PPF), in micromoles per joule, i.e., in the number of light quanta in the range of 400–700 nm emitted by a lamp that consumed 1 J of electricity.

- Yield Photon Flux (YPF), in effective micromoles per joule, i.e., in the number of quanta per 1 J of electricity, taking into account the multiplier - the curve McCree.

Efficiency of DNAT

Large agricultural enterprises with extensive experience and counting money still use sodium lamps. Yes, they willingly agree to hang the LED lamps provided to them over the experimental beds, but they do not agree to pay for them.

From Fig. 2 shows that the efficiency of a sodium lamp is highly dependent on power and reaches a maximum at 600 W. Characteristic optimistic value YPF for a sodium lamp 600–1000 W is 1.5 eff. µmol/J. Sodium lamps 70–150 W are one and a half times less efficient.

Rice. 2. Typical spectrum of a sodium lamp for plants (left). Efficiency in lumens per watt and in effective micromoles of commercial sodium greenhouse light brands Cavita, E-Papillon, "Galad" and "Reflex" (right)

Any LED lamp with an efficiency of 1.5 eff. µmol/W and reasonable price, can be considered a worthy replacement for a sodium lamp.

The questionable effectiveness of red-blue phytolights

In this article we do not present the absorption spectra of chlorophyll because it is incorrect to refer to them in a discussion of the use of light flux by a living plant. Chlorophyll invitro, isolated and purified, only really absorbs red and blue light. In a living cell, pigments absorb light in the entire range of 400–700 nm and transfer its energy to chlorophyll. The energy efficiency of light in a sheet is determined by the curve " McCree 1972"(Fig. 3).

Rice. 3. V(λ) - visibility curve for humans; RQE- relative quantum efficiency for the plant ( McCree 1972); σ r And σ fr- absorption curves of red and far-red light by phytochrome; B(λ) - phototropic efficiency of blue light

Note: the maximum efficiency in the red range is one and a half times higher than the minimum efficiency in the green range. And if you average the efficiency over a somewhat wide band, the difference becomes even less noticeable. In practice, the redistribution of part of the energy from the red range to the green range sometimes, on the contrary, enhances the energy function of light. Green light passes through the thickness of the leaves to the lower tiers, the effective leaf area of the plant increases sharply, and the yield of, for example, lettuce increases.

Plant lighting with white LEDs

The energy feasibility of lighting plants with common LED white light lamps was studied in the work.

The characteristic shape of the spectrum of a white LED is determined by:

- the balance of short and long waves, correlating with color temperature (Fig. 4, left);

- the degree of spectral occupancy, which correlates with color rendering (Fig. 4, right).

Rice. 4. Spectra of white LED light with the same color rendering, but different color temperature CCT (left) and with the same color temperature and different color rendering R a (right)

The differences in the spectrum of white diodes with the same color rendering and the same color temperature are subtle. Consequently, we can evaluate spectrum-dependent parameters only by color temperature, color rendering and luminous efficiency - parameters that are written on the label of a conventional white light lamp.

The results of the analysis of the spectra of serial white LEDs are as follows:

1. In the spectrum of all white LEDs, even with a low color temperature and maximum color rendering, like sodium lamps, there is very little far-red (Fig. 5).

Rice. 5. White LED spectrum ( LED 4000K R a= 90) and sodium light ( HPS) in comparison with the spectral functions of plant sensitivity to blue ( B), red ( A_r) and far red light ( A_fr)

Under natural conditions, a plant shaded by a canopy of alien foliage receives more distant red than near red, which in light-loving plants triggers the “shade avoidance syndrome” - the plant stretches upward. Tomatoes, for example, at the growth stage (not seedlings!) need far red to stretch, increase growth and the total occupied area, and therefore the harvest in the future.

Accordingly, under white LEDs and under sodium light the plant feels like it is under the open sun and does not stretch upward.

2. Blue light is needed for the “sun tracking” reaction (Fig. 6).

Rice. 6. Phototropism - turning leaves and flowers, stretching stems towards the blue component of white light (illustration from Wikipedia)

One watt of white LED light contains twice as much phytoactive blue component as one watt of sodium light. Moreover, the proportion of phytoactive blue in white light increases in proportion to the color temperature. If, for example, you need to turn decorative flowers towards people, they should be illuminated from this side with intense cold light, and the plants will turn around.

3. The energy value of light is determined by color temperature and color rendering and can be determined with an accuracy of 5% using the formula:

where is the luminous efficiency in lm/W, is the general color rendering index, is the correlated color temperature in Kelvin.

Examples of using this formula:

A. Let us estimate for the basic values of the parameters of white light what the illumination should be in order to provide, for example, 300 eff. for a given color rendering and color temperature. µmol/s/m2:

It can be seen that the use of warm white light with high color rendering allows the use of slightly lower illumination levels. But if we take into account that the luminous efficiency of warm light LEDs with high color rendering is somewhat lower, it becomes clear that by choosing color temperature and color rendering there is no energetically significant win or loss. You can only adjust the proportion of phytoactive blue or red light.

B. Let's evaluate the applicability of a typical general purpose LED grow light for growing microgreens.

Let a lamp measuring 0.6 × 0.6 m consume 35 W and have a color temperature of 4000 TO, color rendition Ra= 80 and luminous efficiency 120 lm/W. Then its efficiency will be YPF= (120/100)⋅(1.15 + (35⋅80 − 2360)/4000) eff. µmol/J = 1.5 eff. µmol/J. Which, when multiplied by the consumed 35 W, will be 52.5 eff. µmol/s.

If such a lamp is lowered low enough above a bed of microgreens with an area of 0.6 × 0.6 m = 0.36 m 2 and thereby avoiding light loss to the sides, the lighting density will be 52.5 eff. µmol/s / 0.36m 2 = 145 eff. µmol/s/m2. This is approximately half the usually recommended values. Therefore, the power of the lamp must also be doubled.

Direct comparison of phytoparameters of different types of lamps

Let's compare the phytoparameters of a conventional office ceiling LED lamp produced in 2016 with specialized phytoluminaires (Fig. 7).

Rice. 7. Comparative parameters of a typical 600W sodium lamp for greenhouses, a specialized LED phytolight and a lamp for general indoor lighting

It can be seen that an ordinary general lighting lamp with the diffuser removed when lighting plants is not inferior in energy efficiency to a specialized sodium lamp. It is also clear that the red-blue light phyto-lamp (the manufacturer is deliberately not named) is made at a lower technological level, since its total efficiency (the ratio of the power of the luminous flux in watts to the power consumed from the network) is inferior to the efficiency of an office lamp. But if the efficiency of red-blue and white lamps were the same, then the phytoparameters would also be approximately the same!

It is also clear from the spectra that the red-blue phyto-luminaire is not narrow-band, its red hump is wide and contains much more far-red red than that of the white LED and sodium lamp. In cases where far-red is required, using such a luminaire alone or in combination with other options may be advisable.

Assessment of the energy efficiency of the lighting system as a whole:

Rice. 8. Audit of phytolighting system

Next model UPRtek- spectrometer PG100N According to the manufacturer, it measures micromoles per square meter, and, more importantly, the luminous flux in watts per square meter.

Measuring luminous flux in watts is an excellent feature! If you multiply the illuminated area by the luminous flux density in watts and compare it with the consumption of the lamp, the energy efficiency of the lighting system becomes clear. And this is the only indisputable efficiency criterion today, which in practice differs by an order of magnitude for different lighting systems (and not by several times, or even more so by percentages, as the energy effect changes when the shape of the spectrum changes).

Examples of using white light

Examples of lighting hydroponic farms with both red-blue and white light are described (Fig. 9).

Rice. 9. From left to right and top to bottom farms: Fujitsu, Sharp, Toshiba, a medicinal herb farm in Southern California

The farm system is quite well known Aerofarms(Fig. 1, 10), the largest of which was built near New York. Under white LED lamps in Aerofarms They grow more than 250 types of greens, harvesting over twenty harvests a year.

Rice. 10. Farm Aerofarms in New Jersey ("Garden State") on the border with New York

Direct experiments comparing white and red-blue LED lighting

There are very few published results of direct experiments comparing plants grown under white and red-blue LEDs. For example, this result was briefly shown by the Moscow Agricultural Academy named after. Timiryazev (Fig. 11).

Rice. 11. In each pair, the plant on the left is grown under white LEDs, on the right - under red-blue LEDs (from presentations I. G. Tarakanova, Department of Plant Physiology, Moscow Agricultural Academy named after. Timiryazev)

Beijing Aviation and Space University published the results of a large study of wheat grown under different types of LEDs in 2014. Chinese researchers have concluded that it is advisable to use a mixture of white and red light. But if you look at the digital data from the article (Fig. 12), you notice that the difference in parameters for different types of lighting is by no means radical.

Figure 12. Values of the studied factors in two phases of wheat growth under red, red-blue, red-white and white LEDs

However, the main focus of research today is to correct the shortcomings of narrowband red-blue lighting by adding white light. For example, Japanese researchers found an increase in the weight and nutritional value of lettuce and tomatoes when white light was added to red light. In practice, this means that if the aesthetic appeal of a plant during growth is not important, it is not necessary to abandon the already purchased narrow-band red-blue lamps; white light lamps can be used additionally.

The influence of light quality on the result

The fundamental law of ecology “Liebig barrel” (Fig. 13) states: development is limited by the factor that most deviates from the norm than others. For example, if water, minerals and CO 2, but the light intensity is 30% of the optimal value - the plant will produce no more than 30% of the maximum possible yield.

Rice. 13. Illustration of the limiting factor principle from training video on YouTube

The plant's response to light: the intensity of gas exchange, consumption of nutrients from solution and synthesis processes is determined in the laboratory. The responses characterize not only photosynthesis, but also the processes of growth, flowering, and the synthesis of substances necessary for taste and aroma.

In Fig. Figure 14 shows the plant's response to changes in the wavelength of light. The intensity of sodium and phosphorus intake from the nutrient solution was measured by mint, strawberries and lettuce. Peaks in such graphs are signs that a specific chemical reaction is being stimulated. The graphs show that excluding some ranges from the full spectrum for the sake of saving is the same as removing some of the piano keys and playing a melody on the remaining ones.

Rice. 14. The stimulating role of light for the consumption of nitrogen and phosphorus by mint, strawberries and lettuce (data provided by Fitex company)

The principle of the limiting factor can be extended to individual spectral components - for a full result, in any case, the full spectrum is needed. Removing some ranges from the full spectrum does not lead to a significant increase in energy efficiency, but the “Liebig barrel” may work - and the result will be negative.

Examples demonstrate that ordinary white LED light and specialized “red-blue phytolight” have approximately the same energy efficiency when lighting plants. But broadband white comprehensively satisfies the needs of the plant, which are expressed not only in stimulating photosynthesis.

Removing green from the continuous spectrum so that the light turns from white to violet is a marketing ploy for buyers who want a “special solution” but are not qualified customers.

White light adjustment

The most common general purpose white LEDs have poor color rendering Ra= 80, which is due primarily to the lack of red color (Fig. 4).

The lack of red in the spectrum can be compensated by adding red LEDs to the lamp. Such a solution is promoted by, for example, CREE. The logic of the “Liebig barrel” suggests that such an additive will not harm if it is truly an additive and not a redistribution of energy from other ranges in favor of red.

Interesting and important work was carried out in 2013–2016 by the Institute of Biomedical Problems of the Russian Academy of Sciences: they studied how the addition of 4000 white LEDs to the light affects the development of Chinese cabbage TO / Ra= 70 light narrowband red LEDs 660 nm.

And we found out the following:

- Under LED light, cabbage grows about the same as under sodium light, but it has more chlorophyll (the leaves are greener).

- The dry weight of the crop is almost proportional to the total amount of light in moles received by the plant. More light - more cabbage.

- The concentration of vitamin C in cabbage increases slightly with increasing illumination, but increases significantly with the addition of red light to white light.

- A significant increase in the proportion of the red component in the spectrum significantly increased the concentration of nitrates in the biomass. It was necessary to optimize the nutrient solution and introduce part of the nitrogen in ammonium form so as not to exceed the maximum permissible concentration for nitrates. But in pure white light it was possible to work only with the nitrate form.

- At the same time, an increase in the proportion of red in the total light flux has almost no effect on the weight of the crop. That is, replenishment of the missing spectral components affects not the quantity of the crop, but its quality.

- The higher moles per watt efficiency of a red LED means that adding red to white is also energetically efficient.

Options for enriching the spectrum with red light

The plant does not know where the quantum from the spectrum of white light came from, and where the “red” quantum came from. There is no need to make a special spectrum in one LED. And there is no need to shine red and white light from one special phyto-lamp. It is enough to use general-purpose white light and additionally illuminate the plant with a separate red light lamp. And when a person is near the plant, the red light can be turned off using a motion sensor to make the plant look green and pretty.

But the opposite solution is also justified - by selecting the composition of the phosphor, expand the spectrum of the white LED towards long waves, balancing it so that the light remains white. And you get white light with extra-high color rendering, suitable for both plants and humans.

Open questions

It is possible to identify the role of the ratio of far and near red light and the advisability of using the “shade avoidance syndrome” for different crops. One can argue into which areas during analysis it is advisable to divide the wavelength scale.

It can be discussed whether the plant needs wavelengths shorter than 400 nm or longer than 700 nm for stimulation or regulatory function. For example, there is a private report that ultraviolet radiation significantly affects the consumer qualities of plants. Among other things, red-leaved varieties of lettuce are grown without ultraviolet light, and they grow green, but before sale they are irradiated with ultraviolet light, they turn red and are sent to the counter. And is the new metric correct? PBAR (plant biologically active radiation), described in the standard ANSI/ASABE S640, Quantities and Units of Electromagnetic Radiation for Plants (Photosynthetic Organisms, prescribes taking into account the range of 280–800 nm.

Conclusion

Chain stores choose more shelf-stable varieties, and then the buyer votes with rubles for brighter fruits. And almost no one chooses the taste and aroma. But as soon as we become richer and begin to demand more, science will instantly provide the necessary varieties and recipes for the nutrient solution.

And in order for the plant to synthesize everything that is needed for taste and aroma, it will require lighting with a spectrum containing all the wavelengths to which the plant will react, i.e., in the general case, a continuous spectrum. Perhaps the basic solution will be white light with high color rendering.

Acknowledgments

The author expresses sincere gratitude for the assistance in preparing the article to the employee of the State Scientific Center of the Russian Federation-IMBP RAS Ph.D. n. Irina Konovalova; the head of the Fiteks project, Tatyana Trishina; company specialist CREE Mikhail Chervinsky

Literature

Literature

1. Son K-H, Oh M-M. Leaf shape, growth, and antioxidant phenolic compounds of two lettuce cultivars grown under various combinations of blue and red light-emitting diodes // Hortscience. – 2013. – Vol. 48. – P. 988-95.

2. Ptushenko V.V., Avercheva O.V., Bassarskaya E.M., Berkovich Yu A., Erokhin A.N., Smolyanina S.O., Zhigalova T.V., 2015. Possible reasons for a decline in the growth of Chinese cabbage under combined narrowband red and blue light in comparison with illumination by high- pressure sodium lamp. Scientia Horticulturae https://doi.org/10.1016/j.scienta.2015.08.021

3. Sharakshane A., 2017, Whole high-quality light environment for humans and plants. https://doi.org/10.1016/j.lssr.2017.07.001

4. C. Dong, Y. Fu, G. Liu & H. Liu, 2014, Growth, Photosynthetic Characteristics, Antioxidant Capacity and Biomass Yield and Quality of Wheat (Triticum aestivum L.) Exposed to LED Light Sources with Different Spectra Combinations

5. Lin K.H., Huang M.Y., Huang W.D. et al. The effects of red, blue, and white light-emitting diodes on the growth, development, and edible quality of hydroponically grown lettuce (Lactuca sativa L. var. capitata) // Scientia Horticulturae. – 2013. – V. 150. – P. 86–91.

6. Lu, N., Maruo T., Johkan M., et al. Effects of supplemental lighting with light-emitting diodes (LEDs) on tomato yield and quality of single-truss tomato plants grown at high planting density // Environ. Control. Biol. – 2012. Vol. 50. – P. 63–74.

7. Konovalova I.O., Berkovich Yu.A., Erokhin A.N., Smolyanina S.O., O.S. Yakovleva, A.I. Znamensky, I.G. Tarakanov, S.G. Radchenko, S.N. Lapach. Justification of optimal plant lighting regimes for the Vitacycle-T space greenhouse. Aerospace and environmental medicine. 2016. T. 50. No. 4.

8. Konovalova I.O., Berkovich Yu.A., Erokhin A.N., Smolyanina S.O., Yakovleva O.S., Znamensky A.I., Tarakanov I.G., Radchenko S.G., Lapach S.N., Trofimov Yu.V., Tsvirko V.I. Optimization of the LED lighting system of a vitamin space greenhouse. Aerospace and environmental medicine. 2016. T. 50. No. 3.

9. Konovalova I.O., Berkovich Yu.A., Smolyanina S.O., Pomelova M.A., Erokhin A.N., Yakovleva O.S., Tarakanov I.G. The influence of light regime parameters on the accumulation of nitrates in the above-ground biomass of Chinese cabbage (Brassica chinensis L.) when grown with LED irradiators. Agrochemistry. 2015. No. 11.

Tags:

- light

- lighting

- phytolight

- plants

- gika plants

- LEDs

- quality of life

A band with a maximum in the yellow area (the most common design). The emission of the LED and phosphor, when mixed, produce white light of various shades.

Encyclopedic YouTube

1 / 5

✪ Short white LEDs

✪ White LED vs Red Blue White LED Grow Test - Amazon Lights (Intro)

✪ Cool White Vs Neutral White LED"s In Flashlights (Thrunite TN12 Models)

✪ White LED vs Red/Blue LED Grow light Grow Test - Part 1 (Educational) 2016

✪ White LED vs Red Blue White LED Grow Test w/Time Lapse - Lettuce Ep.1

Subtitles

History of invention

The first red semiconductor emitters for industrial use were obtained by N. Kholonyak in 1962. In the early 70s, yellow and green LEDs appeared. The light output of these, at that time still inefficient, devices reached one lumen by 1990. In 1993, Shuji Nakamura, an engineer at Nichia (Japan), created the first high-brightness blue LED. Almost immediately, LED RGB devices appeared, since blue, red and green colors made it possible to obtain any color, including white. White phosphor LEDs first appeared in 1996. Subsequently, the technology developed rapidly, and by 2005, the luminous efficiency of LEDs reached 100 lm/W or more. LEDs appeared with different shades of glow, the quality of light made it possible to compete with incandescent lamps and already traditional fluorescent lamps. The use of LED lighting devices in everyday life, in indoor and outdoor lighting, has begun.

RGB LEDs

White light can be created by mixing emissions from LEDs of different colors. The most common trichromatic design is made from red (R), green (G) and blue (B) sources, although bichromatic, tetrachromatic and more multi-chromatic variants are found. A multicolor LED, unlike other RGB semiconductor emitters (luminaires, lamps, clusters), has one complete housing, most often similar to a single-color LED. The LED chips are located next to each other and share a common lens and reflector. Since semiconductor chips have a finite size and their own radiation patterns, such LEDs most often have uneven angular color characteristics. In addition, to obtain the correct color ratio, it is often not enough to set the design current, since the light output of each chip is unknown in advance and is subject to changes during operation. To set the desired shades, RGB lamps are sometimes equipped with special control devices.

The spectrum of an RGB LED is determined by the spectrum of its constituent semiconductor emitters and has a pronounced line shape. This spectrum is very different from the spectrum of the sun, therefore the color rendering index of the RGB LED is low. RGB LEDs allow you to easily and widely control the color of the glow by changing the current of each LED included in the “triad”, adjusting the color tone of the white light they emit directly during operation - up to obtaining individual independent colors.

Multicolor LEDs have a dependence of luminous efficiency and color on temperature due to the different characteristics of the emitting chips that make up the device, which results in a slight change in the color of the glow during operation. The service life of a multicolor LED is determined by the durability of the semiconductor chips, depends on the design and most often exceeds the service life of phosphor LEDs.

Multicolor LEDs are used primarily for decorative and architectural lighting, in electronic signage and video screens.

Phosphor LEDs

Combining a blue (more often), violet or ultraviolet (not used in mass production) semiconductor emitter and phosphor converter allows you to produce an inexpensive light source with good characteristics. The most common design of such an LED contains a blue gallium nitride semiconductor chip modified with indium (InGaN) and a phosphor with maximum re-emission in the yellow region - yttrium-aluminum garnet doped with trivalent cerium (YAG). Part of the power of the initial radiation of the chip leaves the LED body, dissipating in the phosphor layer, the other part is absorbed by the phosphor and re-emitted in the region of lower energy values. The re-emission spectrum covers a wide region from red to green, but the resulting spectrum of such an LED has a pronounced dip in the green-blue-green region.

Depending on the composition of the phosphor, LEDs with different color temperatures (“warm” and “cold”) are produced. By combining different types of phosphors, a significant increase in color rendering index (CRI or R a) is achieved. As of 2017, there are already LED panels for photography and filming, where color rendering is critical, but such equipment is expensive, and manufacturers are few and far between.

One of the ways to increase the brightness of phosphor LEDs while maintaining or even reducing their cost is to increase the current through the semiconductor chip without increasing its size - increasing the current density. This method is associated with a simultaneous increase in requirements for the quality of the chip itself and the quality of the heat sink. As the current density increases, the electric fields in the volume of the active region reduce the light output. When limiting currents are reached, since areas of the LED chip with different impurity concentrations and different band gap widths conduct current differently, local overheating of the chip areas occurs, which affects the light output and the durability of the LED as a whole. In order to increase the output power while maintaining the quality of spectral characteristics and thermal conditions, LEDs are produced containing clusters of LED chips in one housing.

One of the most discussed topics in the field of polychrome LED technology is its reliability and durability. Unlike many other light sources, an LED changes its light output (efficiency), radiation pattern, and color tint over time, but rarely fails completely. Therefore, to assess the useful life, for example for lighting, a level of reduction in luminous efficiency of up to 70% of the original value (L70) is taken. That is, an LED whose brightness has decreased by 30% during operation is considered to be out of order. For LEDs used in decorative lighting, a dimming level of 50% (L50) is used as a life estimate.

The service life of a phosphor LED depends on many parameters. In addition to the manufacturing quality of the LED assembly itself (the method of attaching the chip to the crystal holder, the method of attaching the current-carrying conductors, the quality and protective properties of the sealing materials), the lifetime mainly depends on the characteristics of the emitting chip itself and on changes in the properties of the phosphor over the course of operation (degradation). Moreover, as numerous studies show, temperature is considered the main factor influencing the service life of an LED.

Effect of temperature on LED service life

During operation, a semiconductor chip emits part of the electrical energy in the form of radiation and part in the form of heat. Moreover, depending on the efficiency of such conversion, the amount of heat is about half or more for the most efficient emitters. The semiconductor material itself has low thermal conductivity; in addition, the materials and design of the housing have a certain non-ideal thermal conductivity, which leads to the heating of the chip to high temperatures (for a semiconductor structure). Modern LEDs operate at chip temperatures in the region of 70-80 degrees. And a further increase in this temperature when using gallium nitride is unacceptable. High temperature leads to an increase in the number of defects in the active layer, leads to increased diffusion, and a change in the optical properties of the substrate. All this leads to an increase in the percentage of non-radiative recombination and absorption of photons by the chip material. An increase in power and durability is achieved by improving both the semiconductor structure itself (reducing local overheating), and by developing the design of the LED assembly, and improving the quality of cooling of the active area of the chip. Research is also being conducted with other semiconductor materials or substrates.

The phosphor is also susceptible to high temperatures. With prolonged exposure to temperature, re-emitting centers are inhibited, and the conversion coefficient, as well as the spectral characteristics of the phosphor, deteriorate. In early and some modern polychrome LED designs, the phosphor is applied directly to the semiconductor material and the thermal effect is maximized. In addition to measures to reduce the temperature of the emitting chip, manufacturers use various methods to reduce the influence of chip temperature on the phosphor. Isolated phosphor technologies and LED lamp designs, in which the phosphor is physically separated from the emitter, can increase the service life of the light source.

The LED body, made of optically transparent silicone plastic or epoxy resin, is subject to aging under the influence of temperature and begins to dim and yellow over time, absorbing part of the energy emitted by the LED. Reflective surfaces also deteriorate when heated - they interact with other elements of the body and are susceptible to corrosion. All these factors together lead to the fact that the brightness and quality of the emitted light gradually decreases. However, this process can be successfully slowed down by ensuring efficient heat removal.

Phosphor LED design

A modern phosphor LED is a complex device that combines many original and unique technical solutions. The LED has several main elements, each of which performs an important, often more than one function:

All LED design elements experience thermal stress and must be selected taking into account the degree of their thermal expansion. And an important condition for a good design is manufacturability and low cost of assembling an LED device and installing it in a lamp.

Brightness and quality of light

The most important parameter is not even the brightness of the LED, but its luminous efficiency, that is, the light output from each watt of electrical energy consumed by the LED. The luminous efficiency of modern LEDs reaches 190 lm/W. The theoretical limit of the technology is estimated at more than 300 lm/W. When assessing, it is necessary to take into account that the efficiency of a lamp based on LEDs is significantly lower due to the efficiency of the power source, the optical properties of the diffuser, reflector and other design elements. In addition, manufacturers often indicate the initial efficiency of the emitter at normal temperature, while the temperature of the chip during operation is much higher. This leads to the fact that the actual efficiency of the emitter is 5-7% lower, and that of the lamp is often twice as low.

The second equally important parameter is the quality of the light produced by the LED. There are three parameters to assess the quality of color rendering:

Phosphor LED based on an ultraviolet emitter

In addition to the already widespread combination of a blue LED and YAG, a design based on an ultraviolet LED is also being developed. A semiconductor material capable of emitting in the near ultraviolet region is coated with several layers of a phosphor based on europium and zinc sulfide activated by copper and aluminum. This mixture of phosphors gives re-emission maxima in the green, blue and red regions of the spectrum. The resulting white light has very good quality characteristics, but the efficiency of such conversion is still low. There are three reasons for this [ ]: the first is due to the fact that the difference between the energy of the incident and emitted quanta is lost during fluorescence (turns into heat), and in the case of ultraviolet excitation it is much greater. The second reason is that part of the UV radiation not absorbed by the phosphor does not participate in the creation of the luminous flux, unlike LEDs based on a blue emitter, and an increase in the thickness of the phosphor coating leads to an increase in the absorption of luminescent light in it. And finally, the efficiency of ultraviolet LEDs is significantly lower than that of blue ones.

Advantages and disadvantages of phosphor LEDs

Considering the high cost of LED lighting sources compared to traditional lamps, there are compelling reasons to use such devices:

But there are also disadvantages:

Lighting LEDs also have features inherent in all semiconductor emitters, taking into account which the most successful application can be found, for example, the direction of radiation. The LED shines only in one direction without the use of additional reflectors and diffusers. LED luminaires are best suited for local and directional lighting.

Prospects for the development of white LED technology

Technologies for producing white LEDs suitable for lighting purposes are under active development. Research in this area is stimulated by increased public interest. The prospect of significant energy savings is attracting investment in process research, technology development and the search for new materials. Judging by the publications of manufacturers of LEDs and related materials, specialists in the field of semiconductors and lighting engineering, it is possible to outline development paths in this area:

See also

Notes

- , p. 19-20.

- MC-E LEDs from Cree, containing red, green, blue and white emitters Archived November 22, 2012.

- LEDs VLMx51 from Vishay, containing red, orange, yellow and white emitters(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Multicolor LEDs XB-D and XM-L from Cree(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- LEDs XP-C from Cree, containing six monochromatic emitters(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Nikiforov S.“S-class” of semiconductor lighting technology // Components and Technologies: magazine. - 2009. - No. 6. - pp. 88-91.

- Truson P. Halvardson E. Advantages of RGB LEDs for lighting devices // Components and Technologies: magazine. - 2007. - No. 2.

- , p. 404.

- Nikiforov S. Temperature in the life and operation of LEDs // Components and Technologies: magazine. - 2005. - No. 9.

- LEDs for interior and architectural lighting(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Xiang Ling Oon. LED solutions for architectural lighting systems // Semiconductor lighting technology: magazine. - 2010. - No. 5. - pp. 18-20.

- RGB LEDs for use in electronic scoreboards(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- High CRI LED Lighting | Yuji LED (undefined) . yujiintl.com. Retrieved December 3, 2016.

- Turkin A. Gallium nitride as one of the promising materials in modern optoelectronics // Components and Technologies: Journal. - 2011. - No. 5.

- LEDs with high CRI values(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Cree's EasyWhite Technology(English) . LEDs Magazine. Retrieved November 10, 2012. Archived November 22, 2012.

- Nikiforov S., Arkhipov A. Features of determining the quantum yield of LEDs based on AlGaInN and AlGaInP at different current densities through the emitting crystal // Components and Technologies: Journal. - 2008. - No. 1.

- Nikiforov S. Now electrons can be seen: LEDs make electric current very visible // Components and Technologies: magazine. - 2006. - No. 3.

- LEDs with a matrix arrangement of a large number of semiconductor chips(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Service life of white LEDs(English) . U.S. Department of Energy. Retrieved November 10, 2012. Archived November 22, 2012.

- Types of LED defects and analysis methods(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- , p. 61, 77-79.

- LEDs from SemiLEDs(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- GaN-on-Si Silicon LED Research Program(English) . LED Professional. Retrieved November 10, 2012.

- Cree's isolated phosphor technology(English) . LED Professional. Retrieved November 10, 2012. Archived November 22, 2012.

- Turkin A. Semiconductor LEDs: history, facts, prospects // Semiconductor lighting technology: magazine. - 2011. - No. 5. - pp. 28-33.